Printed Concrete Modules

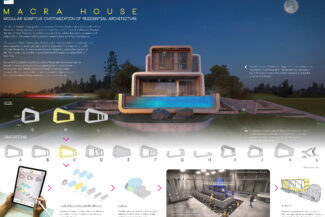

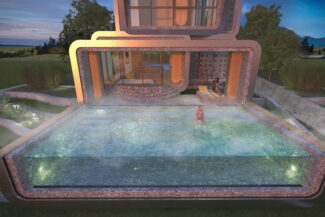

MACRA House is our competition entry for modular housing.

The Process

1. Size, Variation and Quantity Selection

The process begins with the home owner choosing the number, size and variation of modules to be used in the design

2. Design

With the assistance of an Architect the home is customized in detail. One of endless possible configurations is represented here

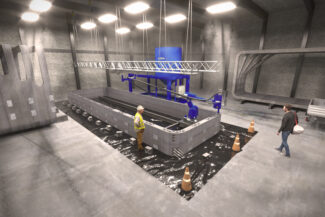

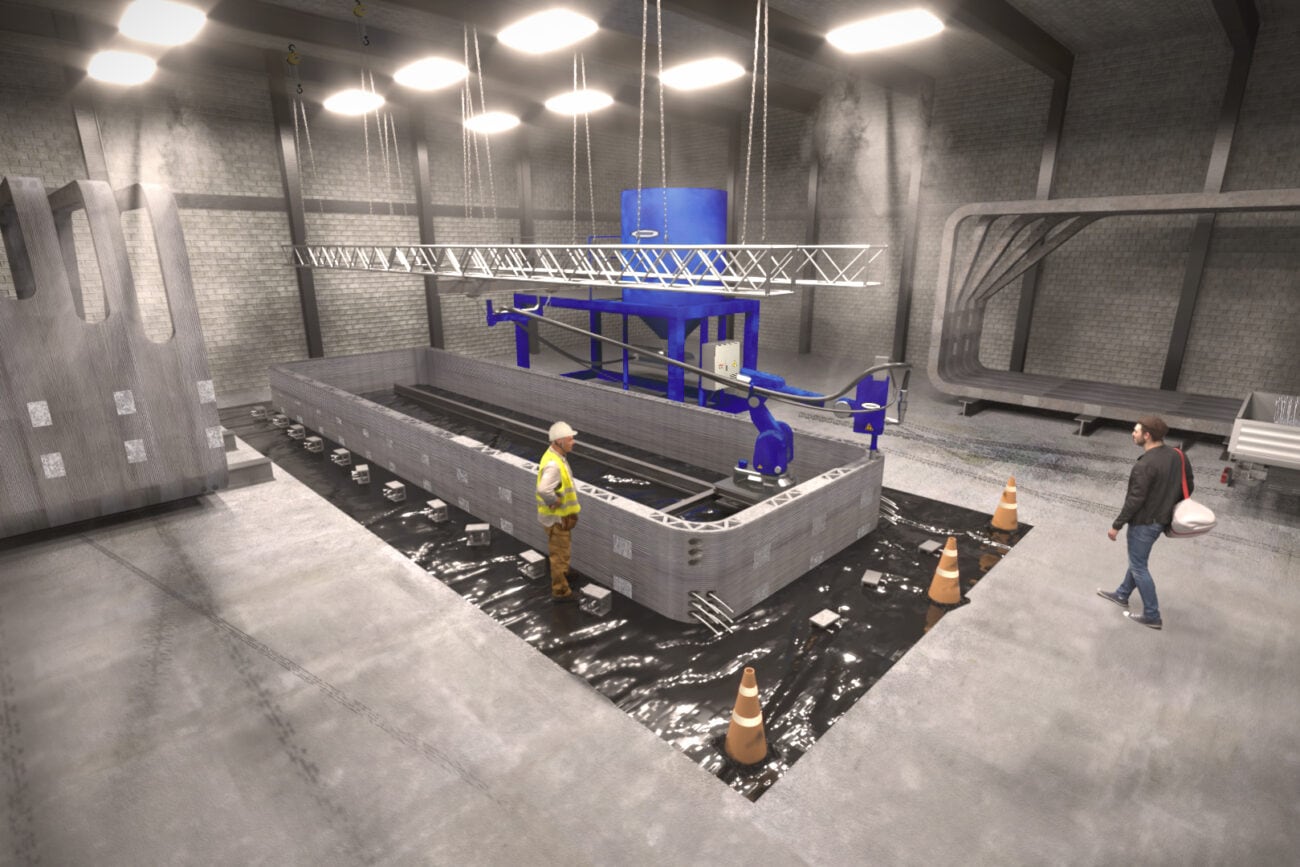

3. Fabrication

Modules are made in the factory;

Simpler modules may be pre-cast, on-site or in the factory, rather than printed

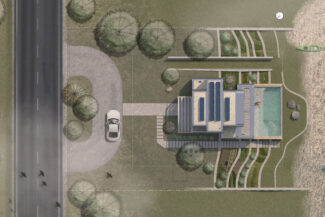

4. Delivery

Modules are delivered to site for installation after site preparations are completed; Modules are braced with steel for temporary support

As Modules are delivered the site preparation works have been completed. Interior and exterior cladding panels are shipped to site once the Modules are assembled. If on-site storage is available they may be shipped together.

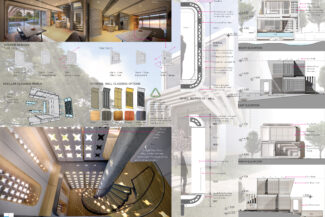

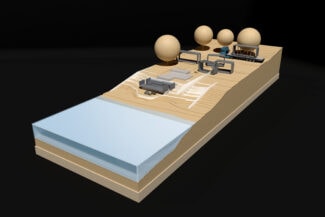

Models are used to illustrate construction sequence as well as the final product.

Once the design is complete a 3D model may be printed and shipped to the home owner for final review.

Printed models can be a used to inform the design process and help the home owner understand every detail of their Modular Home, from the spatial arrangement to the way in which the sun plays on different surfaces of the geometry.

Structure

Several methods of structural reinforcement, such as traditional rebar laid in place, post tension cables, carbon fiber composite and fiber glass reinforcement can be employed depending on the application.

Galvanized steel embeds are set into the printed concrete as they are printed to allow prefabricated panels to be fixed on site and to weld modules together, or to the foundation.

Traditional columns and beams are placed as required.