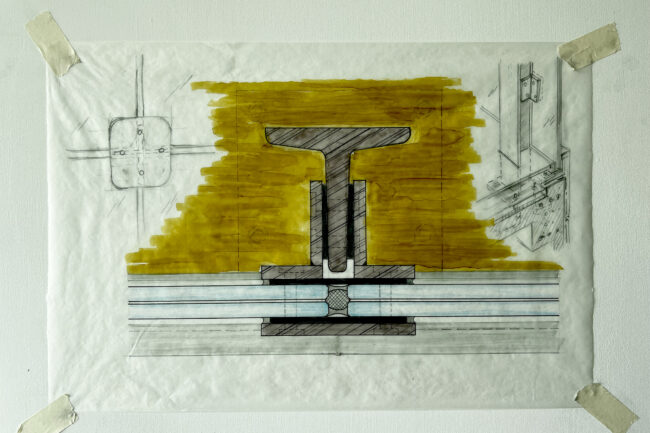

We are studying some façade details for use in some of our projects. The first sketch below is for a stainless steel T-section that supports a laminated, fully tempered glass wall. The brackets in this detail are at intervals but could run continuously depending on the desired effect. This same detail can but used with insulated glass for thermal and acoustic performance improvements where appropriate.

Glass Façade Plan Detail Study

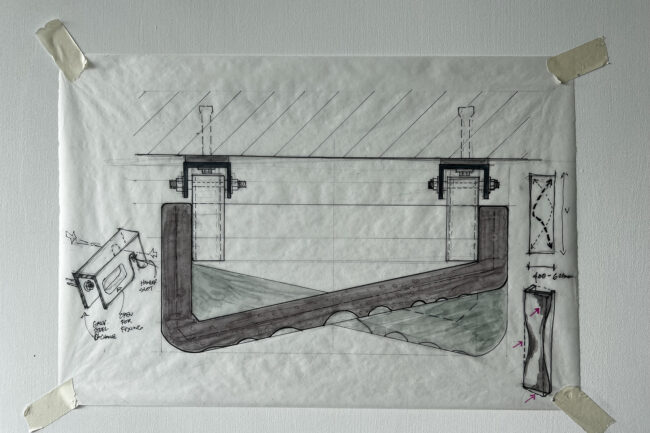

The following detail is for an interior 3-dimensional GRG (glass-reinforced gypsum) panel. The parametric geometry of this panel can be constructed by several means, but the intent, in this case, is to use CNC-milled wax molds to achieve the shape. Several modules would be designed and milled to fit together and when arranged in a specific manner would form a larger pattern on an interior surface.

Parametric GRP – (Gypsum) Panel Detail Study

The indicative semi-circular pattern suggests a form of acoustic diffusion on the panels. The hemispheres could also be penetrations to allow acoustic absorption where required. The size and shape of these opens would vary to form a sub-pattern texture that would be designed and controlled via parametric modeling.