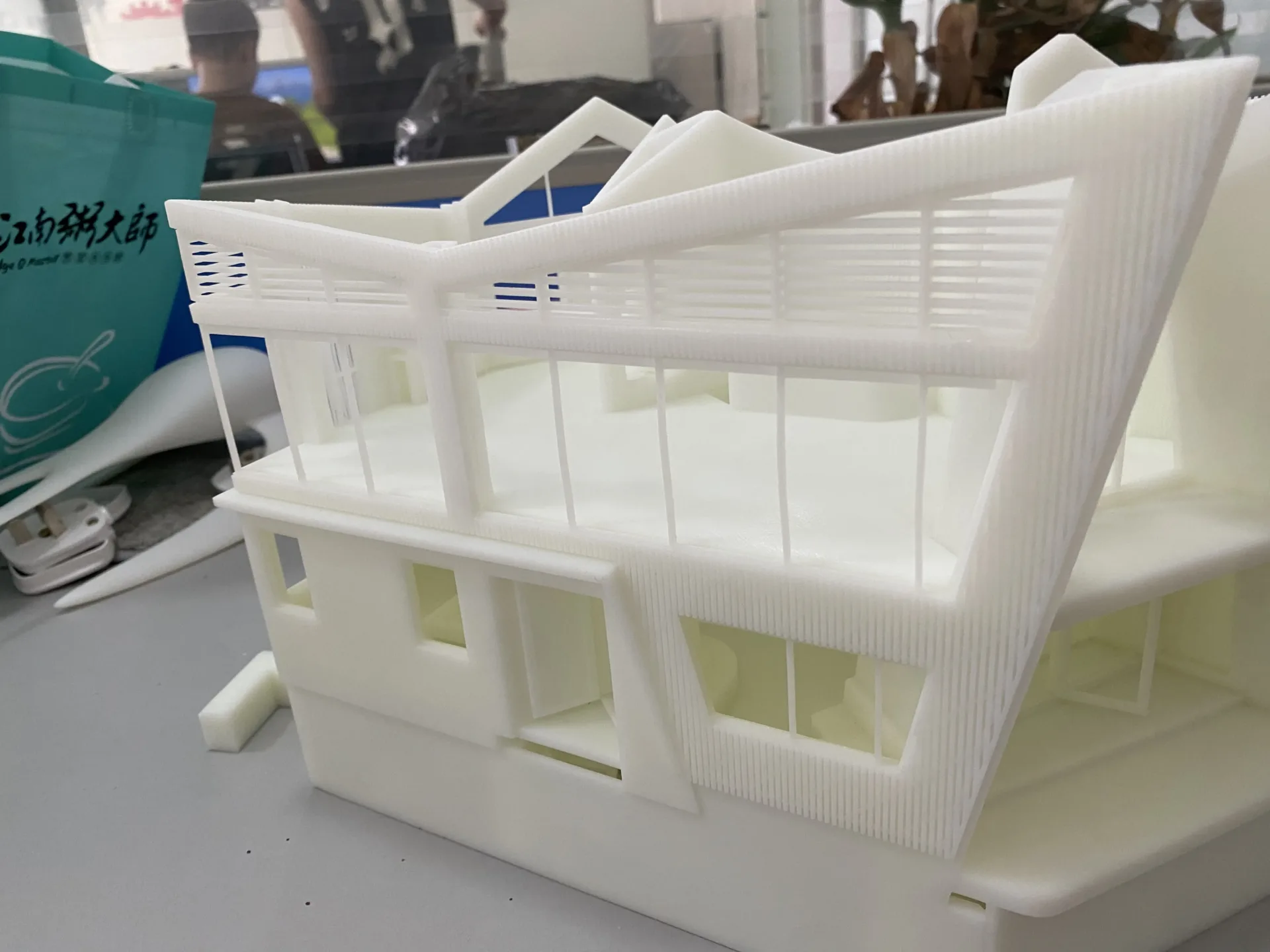

We are in the process of making a physical model for Origami House. Take a look at some of the photos and videos to see the process.

The model is printing on a Union Tech Lite 800 Industrial SLA 3D Printer.

SLA (Stereolithography) resin printing is a form of 3D printing that uses a laser to cure liquid resin into solid objects. Here’s a brief summary of how it works:

- Curing Process: A high-precision laser traces the object’s shape onto the surface of liquid resin, hardening it layer by layer.

- Layer Formation: The build platform lowers into the resin vat for each new layer, allowing the laser to cure the next layer on top of the previous one.

- Finishing Steps: After printing, the object is rinsed with a solvent and then post-cured with UV light to ensure strength and stability.

This method is known for its fine details and smooth surface finish, making it popular for intricate designs and prototypes.

Stereolithography is an additive manufacturing process utilizing a vat of liquid UV-curable photopolymer resin and a UV laser to construct parts layer by layer. This method employs UV light to cure photosensitive polymers, resulting in parts that are built up from the resin vat.